Omnichem

Word of mouth is still the best form of advertising. At Ajinomoto Omnichem in Balen, they had heard nothing but good things from their colleagues in Wetteren about Indinox's piping. The specialist from Lokeren can even call himself a house contractor there. In Balen they put Indinox’s reputation to the test with the installation of a new 20-meter-high distillation tower: project manager Stief Goetschalckx and his team more than delivered.

“Communication was open and honest throughout both the tendering and implementation phases. It was clear from the outset that the timing would be tight, but the challenge was tackled with enthusiasm and a strong work ethic. Through good communication, setting the right priorities, and always keeping our promises, we managed to deliver everything on time for the next phase of the project.”

- Omnichem

SERVICES

First contract

Ajinomoto Omnichem is part of Ajinomoto, the global market leader in amino acids with a sharp focus on the development and production of high-quality products for sectors such as pharmaceuticals, specialty chemicals, nutraceuticals, sports nutrition and health & beauty. One of the departments on the site in Balen specializes in nitration and agrochemicals. In September, Indinox won its first contract and it was immediately a major investment.

New distillation column

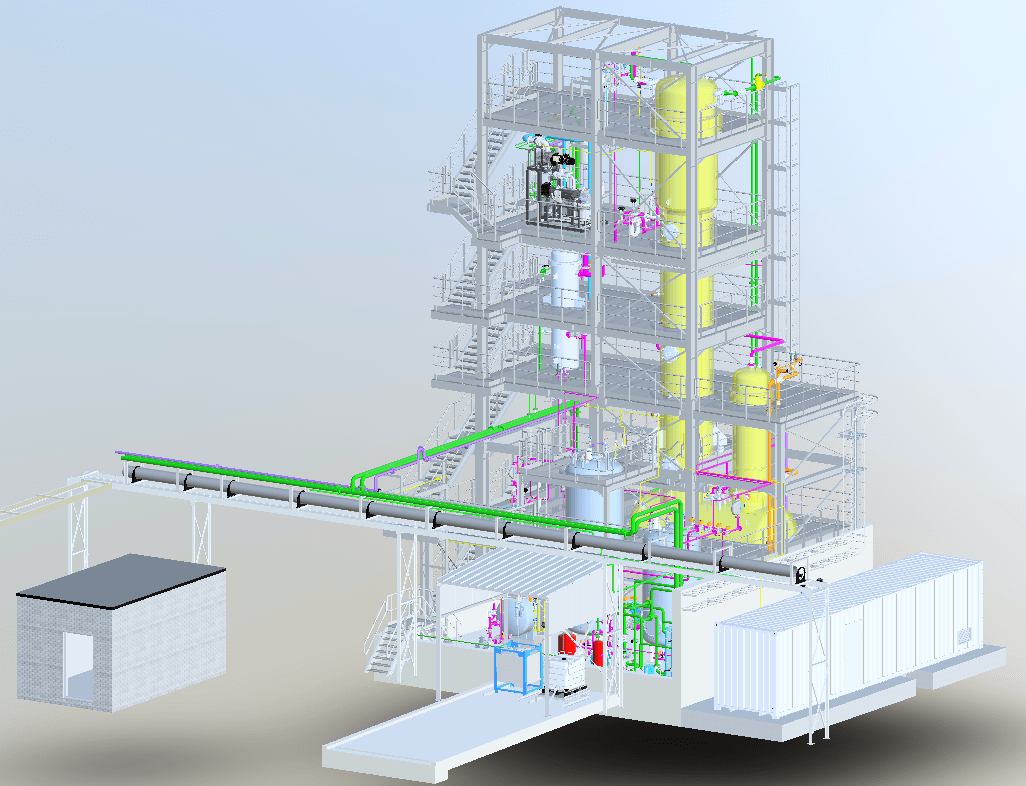

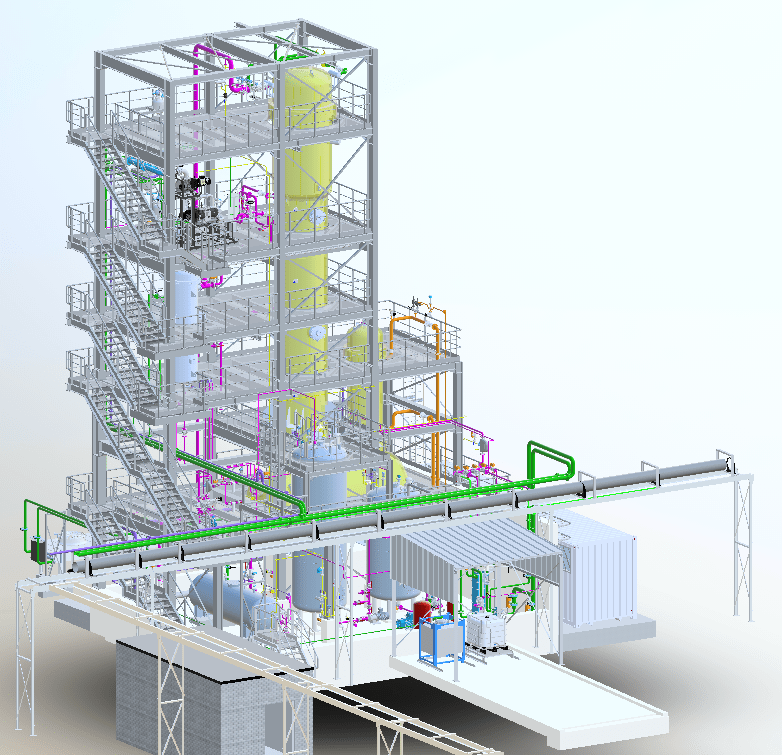

“Omnichem is currently investing heavily in its Belgian sites”, Stief begins. In Balen, for example, it is expanding its capacity with a new distillation column in a 20-meter tower. The medium is distilled by heating thermal oil to a temperature of 300 °C and circulating it over a film evaporator. Thanks to its excellent track record in Wetteren and its competitive offer, Indinox was allowed to provide all the pipework for that project, based on Omnichem's isometrics, 3D drawings and bill of materials.

Second location

For Indinox, this was more than just another project. “We also wanted to use this reference to gain a foothold on the other side of the Kennedytunnel (Kempen/Limburg region). In March, we opened a second branch in Olen on the premises of our sister company Atec.” A challenge that Stief is happy to take on. “There is a lot of potential in that region, but we are obviously not the only player in industrial piping. Nevertheless, I believe that with the quality we deliver and our resolve to stick to our promises, we can automatically make the difference. We have a nice workshop, our own team and a great desire to make a difference.”

Safety first

This project at Omnichem proved it. “We laid the foundation in the workshop, where we prefabricated all the pipes as much as possible. The project lent itself perfectly to this. Everything on site became a matter of plug-and-play. Of course, there is always some TIG welding to be done once you are in the thick of it”, Stief continues. “But thanks to the good preparation, we were able to meet the short delivery deadline.” Even the height difference of the distillation tower couldn’t hold back the team. ”Thanks to our own crane truck and experienced driver, we were able to deliver everything where it was needed."

Focus on quality

“We started with a team of six on site. They did, however, receive additional reinforcements for two weeks. Thanks to this flexibility, no other contractors had to wait for us throughout the entire project. The client was very satisfied with this.” After all, the approach was not the traditional one. The industrial piping was built up step by step along with the rest of the installation. “It was crucial for the client to work with these milestones.”

Enthusiasm and strong work ethic

The end result is impressive, says Omnichem: “Communication was open and honest throughout both the tendering and implementation phases. It was clear from the outset that the timing would be tight, but the challenge was tackled with enthusiasm and a strong work ethic. Through good communication, setting the right priorities, and always keeping our promises, we managed to deliver everything on time for the next phase of the project. A vacuum test down to 0.01 mbara, on an installation with many flange connections, shows that the quality is definitely something to be proud of.”

Keep focus on quality

So, hats off to Stief and his team. “It's nice to see everything come together in the end and to hear that Omnichem is extremely satisfied with the quality delivered. In certain sectors of industry, quality is truly the decisive factor. We want to focus on that.”

Let’s make your project flow

Need a reliable partner for your piping project? Indinox provides an efficient, hands-on comprehensive approach— from enquiry to execution and follow-up.